Promoted by Quickstep

The sustainment efforts that keep military aircraft flying are key to delivering national defence capability. Aircraft procurements are high profile, but the through-life sustainment and upgrade costs required to maintain advantage in an ever-evolving threat environment, are often visible only to those who depend on or manage that platform.

Steve Osborne is General Manager for Business Development at Quickstep Technologies, Australia’s largest independent aerospace composites manufacturer who recently entered the Aerospace MRO & Sustainment services business through acquisition of Boeing’s Component Repair business in Melbourne. After leaving the Royal Australian Air Force, he has worked with Air Forces around the world designing and delivering sustainment models.

“I’ve worked closely with around six different Air Forces over the years, each of those often operating similar Aircraft types, but achieving very different rates of availability. Their sustainment models vary in how operator and industry responsibilities are split, ranging from Air Force does it all, Air Force does only operational maintenance, the Air Force just supplies Pilots; and everything in between.”

Unlike the Commercial Aviation world, there is little global alignment on defence sustainment models. Nor is there likely to be. Factors such as national employment needs, defence budgets and levels of sovereign industrial development all contribute to the model that an Air Force applies to the sustainment of its platforms, but there is one consistent observation Osborne has made during his time spent with different operators; ‘where there is a genuine sovereign sustainment capability, there is much more operational flying conducted per taxpayer dollar spent, and for everyone involved, that’s a successful model.’

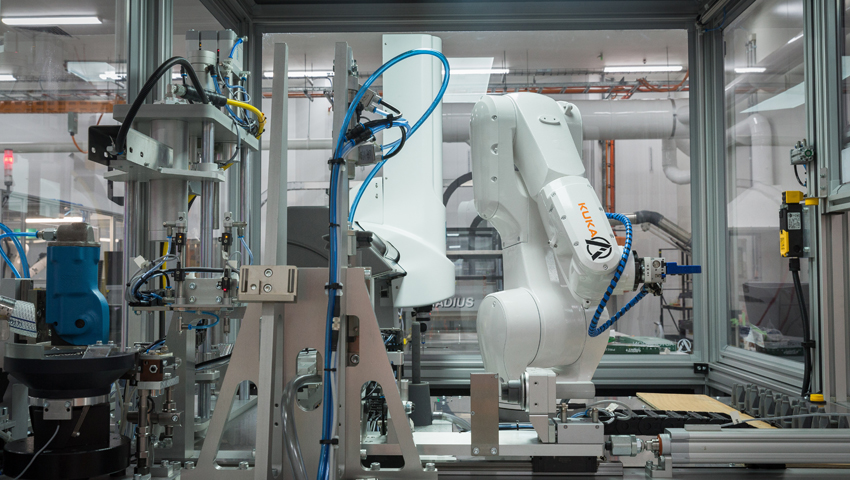

Quickstep acquired Boeing’s component repair capability as a complementary fit to their design, development and production operations. They also saw a growing customer need that extended beyond the Boeing-centric platform work that was happening there. Their high-tolerance, high-complexity manufacturing work on F-35 and other platforms highlighted the importance of maintaining composite repair as a sovereign capability.

Composite and component repair is one of the lower profile defence capabilities. Traditionally with defence platform sustainment, it has been a case of standing up Engine, Avionics and Hydraulic workshops first and the majority of sustainment needs are covered, but now with substantially composite platforms such as the stealthy F-35, UAV’s and increasingly in Rotary Wing, highly skilled composite structural repair is a fundamental onshore need. Add to this the increasing use of composite commercial aircraft being adapted for defence roles such as the Boeing, Airbus and Embraer types and having a world class onshore capability makes good sense.

Australian Industry Capability (AIC) or Global Supply Chain (GSC) policy driven manufacturing opportunities off the back of platform procurements have helped build Australian aerospace companies such as Quickstep. Manufacturing though, is always going to be at the mercy of international OEM’s since Australia does not have a domestic aircraft industry. Market forces such as FX, competing industrial offset requirements of other countries and significant costs added by OEM’s to manage an international supply chain will always impact OEM distribution of work, no matter how good an Australian suppliers price, quality and delivery ratings are.

Sustainment on the other hand, is completely under the control of the operating nation and notwithstanding multi-national programmes such as F-35 or FMS cases, it is Defence themselves that have the sole ability to say where sustainment work is done.

Quickstep’s recent acquisition creates the opportunity to continue and grow a substantial sovereign composites repair capability, but that business in particular has some unique challenges that require a consolidated view to be taken by Defence.

“Unlike other Aircraft components and systems with relatively accurate MTBF data or fixed overhaul schedules, there is limited solid data around composite repair needs other than fatigue lifed components. That makes business cases challenging, but easily overcome with consolidation and aggregation of composite and component repairs. We’ve invested to maintain this sovereign capability and now we need Defence to invest by providing a level playing field and, ultimately, putting work into that facility. When it comes to AIC investment, grants are good, but value add work is an exponentially better investment” says Osborne of the need for Defence to support Quickstep’s investment.

Like many other Australian defence businesses, Quickstep are the fabric of a growing industrial base. Their success will not only be good for the company and its employees, it will also be good for Government, Defence and the wider community.

Login

Login