A RUAG Australia project has shown how supersonic particle deposition (SPD) repair technology can provide cost-savings and maintain platform performance for air forces.

To continue reading the rest of this article, please log in.

Create free account to get unlimited news articles and more!

The project, which has been labelled as an industry milestone, investigated and proved the viability of SPD repair technology for structural components, in this case corroded wing skins on operational aircraft.

The success of the project has provided a more positive outlook for air forces, in terms of continued platform performance and improved cost-savings on maintenance budgets.

The project was led by Neil Matthews, senior manager research and technology at RUAG Australia, and Professor Rhys Jones, head of the Centre of Expertise in Structural Mechanics at Monash University.

The project's paper, titled Additive metal solutions to corroded wing skins in operational aircraft, won the Best Written Paper Award in Additive Manufacturing, at the 17th Australian International Aerospace Congress, held at Avalon 2017.

"This award confirms our passion for investigating technologies, which enable us to serve our customers with the best possible solutions," stated Matthews.

"Testing was performed on operational aircraft replicated structure using operational flight load spectra. The outstanding results are specifically interesting with regards to legacy aircraft, as corrosion related issues represent up to $228 million annual spend on Australian Defence aircraft, and at least 31 per cent of the US Air Force’s annual maintenance costs. These are remarkable sums and are not expected to scale-down, even with the introduction of new aircraft, as air forces need to operate these aircraft longer, due to budget constraints."

RUAG said the paper proves that SPD repairs restore integrity for external patch repairs to skin corrosion, for embedded scarf repairs, and for external patch repairs to inhibit intergranular cracking (IGC). In fact, analysis reveals that SPD repairs on compression surfaces where there is up to a 50 per cent loss of material between the risers can essentially restore the load carrying capacity of the wing, even in the case of stress corrosion cracking in the risers.

"We became aware of the technology’s potential to restore lost structural integrity during our successful certification and incorporation of SPD repair solutions for nonstructural applications (geometry restorations)," explained Matthews.

Jones and Matthews have been collaborating in the further development of this technology in structural applications since 2008 and are considered world leaders on the subject, holding several international patents on behalf of RUAG Australia.

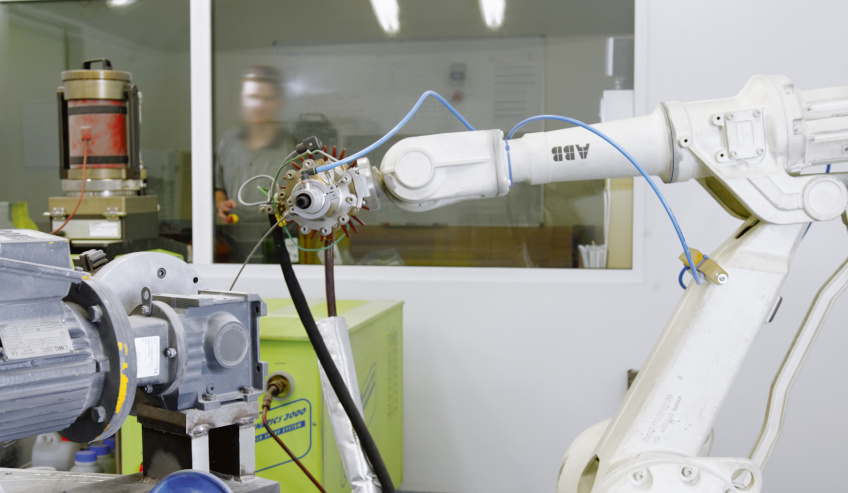

SPD (also referred to as cold spray) is a technology in which metal powder particles are accelerated to supersonic speeds in a high pressure expanded gas flow and impact a solid surface with sufficient energy to cause plastic deformation and bonding with the underlying material.

Login

Login