For more than a decade, Australia’s National Aircraft Pavement Maintenance (NAPM) Program has found increasingly efficient techniques for maintaining the average weighted pavement condition of the country’s 28 Defence airfields. Program veteran design consultant, Beca’s Damian Johnson, reflects on some of its key learnings.

To continue reading the rest of this article, please log in.

Create free account to get unlimited news articles and more!

The NAPM Program has been keeping the Australian Defence Force’s (ADF) airfields operational since 2009. Beca, with our Joint Venture partner Aurecon, has been delivering full design and PMCA (project management and contract administration) services since 2013.

The program has centralised the planning and delivery of minor and CAPEX (capital expenditure) maintenance, by establishing a consistent approach to maintenance and a network-level approach to prioritise works.

Undertaken annually, the program consists of three primary elements:

- 1. Pavement inspection and design documentation process

- 2. Value management and CAPEX Maintenance Planning Workshop

- 3. Construction phase, completion and defects liability period

Efficient aircraft pavement inspection

The visual aircraft pavement inspections form an integral aspect of the wider NAPM Program and are undertaken on foot by a two to three-person design consultant team, depending on the airfield size and complexity. To maintain continuity in approach, the inspection team attempts to use the same experienced personnel at each airfield.

At the time of the inspection, physical works are scoped in detail ahead of upcoming maintenance tasks. This includes marking out key maintenance activities on the ground, such as asphaltic concrete patching and Portland Cement Concrete (PCC) joint spall repair works, while photographing defects and recording their locations.

After the visual inspection, airfield stakeholders receive a briefing and a short exit report by the inspection team, highlighting any areas requiring their immediate attention. Program stakeholders receive a detailed Pavement Inspection Report containing the scoped minor routine maintenance tasks and budget estimate documentation (organised by maintenance trade type). The report also includes a high-level budget estimate of recommendations for a 10-year CAPEX maintenance plan, such as asphaltic concrete overlays, pavement reconstruction and PCC replacement.

A new, app-based condition rating system

Back in 2010, to support consistency and make the pavement assessment process more efficient, Beca co-created with Defence a simple, pragmatic and cost-effective condition rating system for asphaltic concrete, PCC and Interlocking Concrete Block Pavers (ICBP) aircraft pavements. The aim was to use the rating system at each airfield as part of a standard report to better predict deterioration rates and help determine the timing of maintenance treatments.

The Airfield Pavement Condition Rating System, which is described in the Airfield Pavement Maintenance Manual (Defence 2020), uses relative ratings of 7 (“very good”) to 1 (“failed”), with detailed descriptors to ascertain a relative condition rating for each aircraft pavement area at each individual airfield.

The rating system is not as detailed or time consuming as the Pavement Condition Index (PCI) system contained in ASTM D-5340-20 Standard Test Method for Airport Pavement Condition Index Surveys (ASTM 2020), although the condition rating scales adopted are common to both. Typically, using the APMM Rating System, the ADF’s larger Tier 1 airfields take two to three days to inspect while smaller airfields may take less than a day.

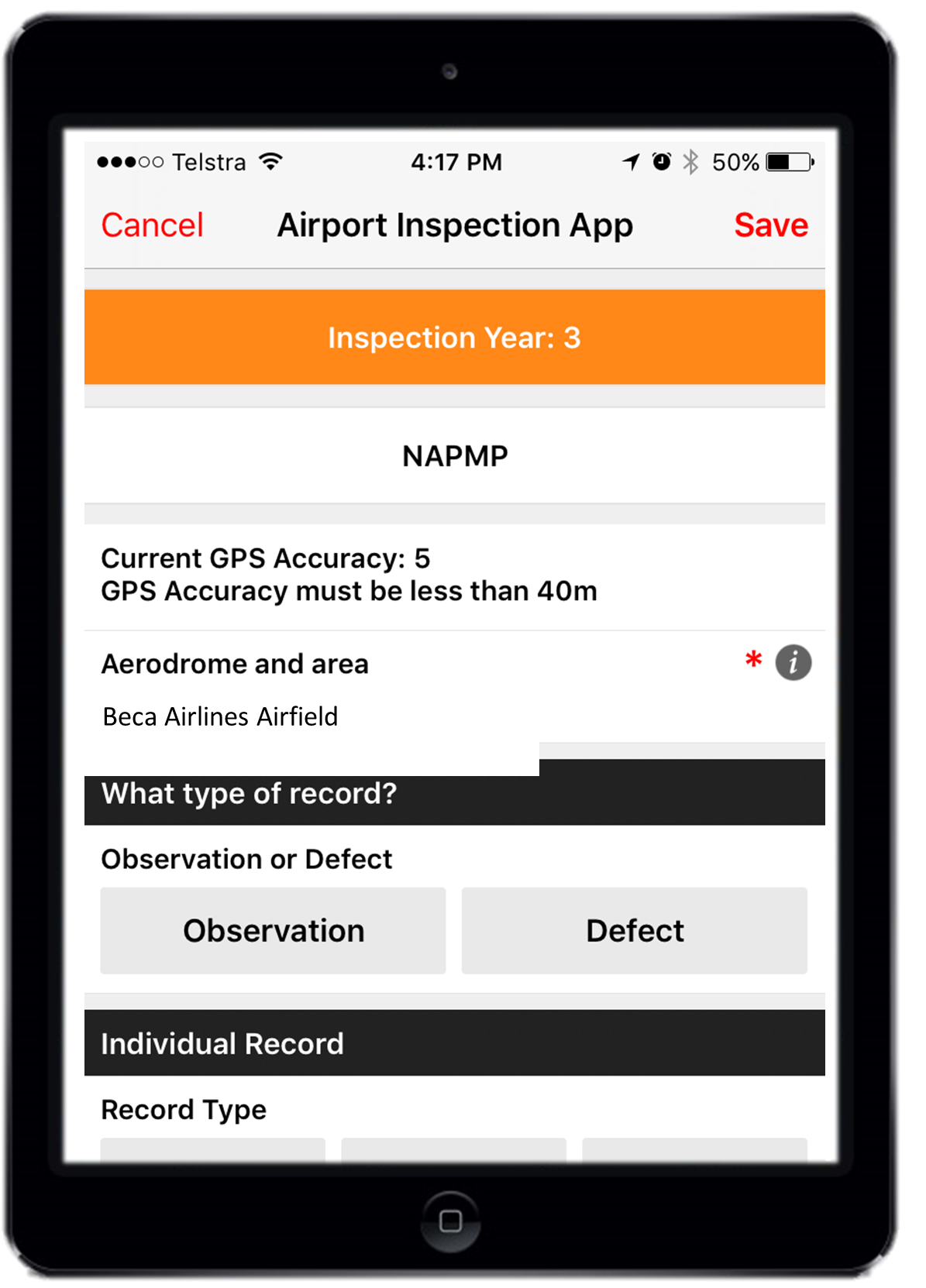

Initially, pavement inspections were documented using digital cameras and site notebooks, with designs and pricing presented using CAD, Excel and Word. Eventually, Beca developed an app that logs observations, defects and maintenance scope with a GPS location by geo-tagging photographs.

Today, Microsoft Office 365, Power BI and GIS reporting are used to analyse and present the data. As a result, condition reporting and design and pricing documentation is analysed and presented more effectively. Airfield stakeholders can drill down into detailed information on each defect, while decision makers can get a network overview of relevant information via a simple, highly visual dashboard. This has helped Defence to plan and prioritise both routine minor maintenance works, and CAPEX maintenance works more accurately and efficiently.

Construction phase: New aircraft pavement maintenance products and techniques

Since 2009, the NAPM Program has trialled new maintenance products and techniques. The most successful have included using:

- Polymer Modified Emulsion (PME) - Surface treatments (typically containing some fine aggregate) in lieu of surface enrichment spray treatments (SESTs) on aged asphaltic concrete pavements. Provided the surface friction values are not “low”, the application of PME results in a marginally higher friction value and texture depth with a reduced permeability. Other benefits over SESTs include shorter curing periods, less weather susceptibility, fewer potential environmental impacts and less health and safety issues.

- A Semi Rigid Epoxy (with Sand) - To repair various PCC defects, including joint spalls, corner breaks, pock marks, surface scaling including heat and fuel damage from aircraft auxiliary power units.

- Rapid Set Cement Concrete - for localised expedient PCC slab replacements.

- Micro Surfacing - (12mm thick) to cost effectively rehabilitate and restore runway friction on aged asphaltic concrete runway pavements at a relatively low usage airfield.

- Stone Mastic Asphaltic (SMA) - As an alternative runway surface. A recent trial was undertaken on a length of taxiway using a performance-based specification for SMA developed by an Air Force Masters student.

An annual workshop to support long-term planning

The annual workshops held between Defence and the design consultant to review the relative condition of the aircraft pavements at each airfield have proven to be extremely valuable. Drawing on the knowledge of operational priorities from various Defence stakeholders, the workshops allow Defence to rapidly determine routine minor maintenance work plans for each airfield and develop an updated 10-year CAPEX Maintenance Plan for major works, to meet the available annual budget.

Positive benefits in long-term contractual arrangements

By sustaining continuity with both design consultants and contractors, Defence has been able to capture lessons learnt and use these to drive continual improvement, by putting mechanisms in place to react quickly to urgent maintenance requirements. This has led to less rework and better value for money outcomes.

Since 2012, the National Aircraft Pavement Maintenance Program has been able to maintain the average weighted pavement condition rating of between 4 and 5 for Tier 1 and Tier 2 airfields, while continually improving efficiency. The new app-based data capture and reporting system, in combination with improved maintenance products and techniques has also supported planning of a major new CAPEX program to further increase pavement condition ratings in the future.

Damian Johnson is a program veteran design consultant at Beca.

Login

Login