Every second, thousands of signals are managed by the Integrated Platform Management System (IPMS) in each of the Navy’s LHDs, AORs and DDGs platforms. For this reason, the IPMS, along with the Combat System, is the key system of our Navy’s newest warships.

Navantia’s Integrated Platform Management System (IPMS), is currently the most advanced “platform control system” operated by the Royal Australian Navy (RAN) and a critical mission system. More than a control system, the IPMS is also an important system for sustainment.

The development of Navantia’s IPMS commenced twenty-five years ago in Spain. Today, more than 90 ships, training centres and simulators around the world are using this technology in its different versions. In Australia, Navantia’s IPMS is installed on 19 RAN vessels as well at several land-based Defence establishments in the form of Through Life Support Land Based Facilities, training centres and simulators, and is supported by a small, dedicated team of Navantia Australia engineers.

Foundation for platform monitoring and control

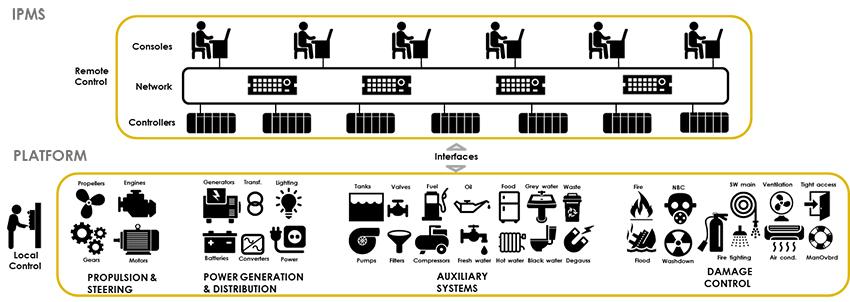

Every second, thousands of signals are managed by the IPMS in each of the LHDs, AORs and DDGs platforms, such as the number of interfaces the system has with the platform system. For this reason, in warships, the IPMS is, along with the Combat System, the key system of the ship as all the platform information is monitored and, in many cases, even controlled.

Navantia's long experience supporting the operability and survival of its vessels is reflected in the IPMS software, ensuring it meets the strictest operational requirements of military ships. It is also backed by the highest safety standards, which is a priority in all Navantia products. The continuous search for safer systems makes the COMPLEX / SIMPLEX framework continually evolve, incorporating the results of multiple R&D and product improvement projects such as continual engineering analysis and feedback and the implementation of the Condition Based Maintenance (CBM), enhancing fault monitoring and prognostics, integration with equipment health monitoring systems, etc.

The IPMS is based on the COMPLEX/SIMPLEX framework, which provides the foundations to build decentralised systems for platform monitoring and control. Based on a combination of state-of-the-art technology and the wide use of reliable, industrial open-architecture components, reliability, redundancy, modularity, flexibility and standardisation of the system is guaranteed as part of the design.

Flexible, Powerful Tool

The IPMS can be integrated in any naval vessel, irrespective of the platform designer. It can be based on Linux and Windows operating systems depending on the Customer’s needs, providing reliable means to prevent data infection and unauthorised software to be installed.

Main features include:

- Distributed architecture - information being available simultaneously at different stations

- Robust fault-tolerant architecture - Physical and logic redundancy

- Open architecture: Scalable and compatible with other systems

- Intuitive and homogeneous user interface

- High speed update of real-time data

- High storage capacity of historical data.

IPMS engineering changes originate from different sources - Platform and/or Combat system modifications, which can have a potential impact into the IPMS interface or IPMS improvement itself. Obsolescence/Technological Refresh can be the third cause of Engineering Change for both Platform and IPMS.

Navantia’s IPMS also supports other solutions to support ships during their whole life.

The IPMS Simulator is a powerful tool to train, not only on the IPMS, but how the platform systems work on board. The Scenario Development allows the trainers to replay any situation lived previously in the platform.

Navantia’s IPMS can be controlled and monitored from a remote position located on shore (Pier Side Monitor) and is capable of working on a common Through Life Support Facility (TLSF) for all the Platforms support.

As a Cost-Effective Maintenance Tool

To support the Product Lifecycle Management (PLM), Navantia IPMS offers a proactive and cost-effective solution to Obsolescence Management for both hardware and software using synergies from different platforms and commonalities.

The IPMS records all the platform historical data on-board. This data is then used in a variety of ways, including two different Navantia platforms – the Playback Centre and Argos21, and other digital technologies being developed by Navantia Australia in our Sydney Data Lab.

Due to the commonality and synergies with other Navantia Platform ships (LHDs, DDGs, AOR), any improvement, lesson learned, proactive obsolescence management, training and spares control can be applied in a cross platform support.

The Human Machine Interface (HMI) application running on the multifunctional workstations installed on-board has the platform functions arranged by service. Each service provides specific mimics for control and monitoring of the ship subsystems. A common structure for organising ship subsystems into services is:

- Ship Control

- Propulsion

- Electrical Power Generation

- Electrical Distribution

- Auxiliaries

- Damage Control

- Diagnostics

An authorised operator is able to control and monitor any service from any multifunctional workstation. Services may be assigned to multifunctional consoles by a user with the appropriate authorisation, and constraints for control and monitoring of services can be initiated if required by the client.

As a general rule, and depending on the assigned systems, the IPMS operator has access to the following capabilities:

- Visualisation of status and the parameters of the systems and equipment

- Modification of operation modes

- Start and stop of equipment

- Change of set points

- Representation of graphs and trend

- Verification of input data integrity (out of range, inconsistent data, etc.)

- Acknowledge and inhibition of alarms.

As a Damage Control Integrated Management System (DCIMS)

Navantia’s Damage Control Integrated System (NADCIS) provides emergency management and monitoring for ships under damage conditions. NADCIS organises and efficiently presents information to help operators understand the situation as it evolves to take the optimum decisions in response to any emergency. NADCIS is the most powerful tool within the COMPLEX/SIMPLEX framework.

Damage Control is defined as the set of provisions, technical and human, and material resources intended to prevent, relieve and correct the effects that may arise from accidents, the enemy's action, on a ship or its equipment, and in modern times of terrorist acts. Thus, the fundamental object of DCIMS is to keep the military effectiveness and sailing capability of the ship at its highest level and maintain, at all times, the maximum offensive power of the vessel.

The pillars on which the achievement of this objective, the Damage Control are based on, are the following:

- Take all preliminary measures to prevent any damage

- Locate and minimise damage as soon as it occurs

- As fast as possible, tackling the emergency repair of damage, repairs of equipment or immediate start implementation, and care of any injured crew.

IPMS Damage Control functionality is based on two cornerstones: (1) control and monitoring capabilities of damage control subsystems; and (2) the Damage Control Integrated Management System (DCIMS) toolset. Damage control subsystems are integrated and synchronised into the IPMS, by providing specific purpose mimics tailored to the ship for monitoring and control of systems involved. The IPMS can provide the Damage Control Integrated Management System to enhance support to the operator in all stages of damage control: detection and location, decision aids, fight, coordination, evolution tracking, etc.

Supporting the DCIMS is a set of tools:

- Integrated 3D damage plot

- Kill Cards

- Interface with CCTV security cameras

- Stability & strength calculations

- Personnel Location System

- Integrated panoramic views

- Optimum Escape Routes

When maintained properly, the IPMS can ensure platform reliability.

As the IPMS is installed on all of the Hobart Class DDGs, Canberra Class LHDs and Landing Craft, as well as the Supply Class AORs, Navantia Australia is uniquely placed to provide not only engineering design services to the RAN, but smarter sustainment solutions. Navantia Australia is able to successfully utilise the data provided by the IPMS, combined with the latest of engineering tools and simulation technology, to undertake the complex tasks of engineering and systems in support of RAN assets. This can be extended to future platforms if also installed, thus offering a higher degree of commonality, interoperability and training efficiencies across the fleet.

Login

Login