Promoted by Dassault Systèmes.

To continue reading the rest of this article, please log in.

Create free account to get unlimited news articles and more!

Virtual experience twins combine real-time operational data with 3D models, simulation and analytics, offering a single source of digital truth and enabling stakeholders across the naval shipbuilding value chain to define, simulate, validate, plan, predict and execute flawlessly at every stage of naval shipbuilding. This allows shipyards to reduce costs, boost efficiency, and improve safety throughout the vessel’s lifecycle.

The world is experiencing a profound global transformation in the way we invent, learn, produce and trade. It is reshaping industries by connecting the virtual world and the real world. It is as great a change as the Renaissance that occurred in Europe from the 14th to the 16th century.

Virtual experience platforms are the infrastructure of this Industry Renaissance. As the only platform that’s both a system of operations and a business model, Dassault Systèmes’ 3DEXPERIENCE platform is the most powerful way for naval shipyards to drive their transformation, enabling them to innovate with operational excellence as well as redefining the relationships across their entire value network, from the navy to their ecosystem of suppliers.

Virtual experience twins are instrumental in enabling the business transformation behind next generation naval shipbuilding. The naval value chain can take advantage of the ship virtual experience twin, from concept to construction to ship in operation, as well as the shipyard virtual twin, to drive its transformation.

Virtual experience twins contribute at every stage of naval shipbuilding

Design Stage: At the design stage, virtual experience twins provide a unique, accurate and shared 3D representation of the ship and its systems, enabling the many disciplines involved – structure, piping, cabling, accommodation, architecture and so on – to define, simulate and optimize all the functions required for naval vessels to fulfill their evolving missions, with traceability from the requirements to the functional, logical and physical design.

Build Stage: The digital continuity offered by the model-based enterprise – that is having all manufacturing blueprints of the ship available as 3D work instructions – allows a perfect transition of design data into production information without any risk of interpretation or misunderstanding. Thanks to digital work orders, any worker on the shop floor always has the right information at the right moment and knows what to do and how to do it.

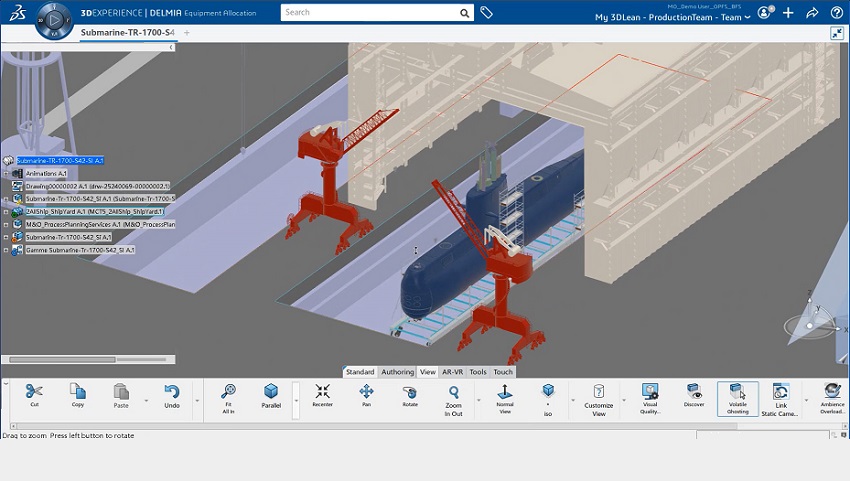

In addition, having a virtual experience twin of the shipyard as well, allows shipbuilders to plan, simulate, and optimize the assembly operations of ships (and submarines) within the virtual shipyard, leveraging the tight links between the ship twin and the shipyard twin.

Operation Stage: The virtual experience twin of the ship offers a bridge between the real world and the virtual world. Data integration with Internet of Things (IoT) devices and sensors during ship operations, allows the optimization of maintenance activities thanks to big data analytics for predictive maintenance. This also provides onboard support to the crew to make ships safer and fully available at sea.

Virtual experience twins enable digital continuity

Digital Continuity is about using a single source of information along the life of the ship from initial requirements to ship in operation, leveraging the use of virtual experience twins.

When manufacturing a naval vessel, digital continuity allows to directly ‘consume’ 3D design information into 3D work instructions used to execute the fabrication; removing thousands of documents and drawings traditionally created and managed during the various steps of the lifecycle.

In model-based manufacturing, we are able to connect preparation, planning, scheduling, execution and monitoring of work orders. This digital continuity offers huge benefits to reduce time and cost while ensuring perfect quality.

With a digital work order, shipbuilders can exchange the same level of data across planning, scheduling, enterprise resource planning systems and execution. Better work preparation enables shipbuilders to increase and improve the pre-assembly and pre-outfitting processes, which, in turn, reduces the time needed for actual assembly operations. Optimized planning ensures that the shipyard floor and dry docks are available at the right time.

For the maintenance of vessels, tasks can be identified and validated within a single platform. At times, the maintenance operation can be tested virtually before execution, allowing safer and faster execution.

Virtual experience twins enable training for the future workforce

By using virtual worlds on a virtual experience platform, the workforce has ready access to knowledge and know-how that allow them to learn faster and think more broadly. The result is that businesses can move from optimizing individual disciplines in silos to connecting them for timely and quality deliveries.

The virtual experience twin integrates a host of technologies to improve business operations and outcomes, design, production, operations, maintenance, and even procurement, marketing and sales. Advanced organizations across industries are already realizing the benefits and many more are investing in this technology as part of their digital transformation programs.

François Mathieu provides counsel to businesses in the marine and offshore industry on digital transformation projects.

For more information on the power of digital transformation and delivering complex ships with confidence and efficiency, download our ebook here: https://go.3ds.com/AUf

Dassault Systèmes, the 3DEXPERIENCE® Company, provides business and people with virtual universes to imagine sustainable innovations. Our 3DEXPERIENCE® platform powers our brand applications, serving 11 industries, and provides a rich portfolio of industry solution experiences. Our world-leading solutions transform the way products are designed, produced, and supported. Dassault Systèmes’ collaborative solutions foster social innovation, expanding possibilities for the virtual world to improve the real world. The group brings value to over 250,000 customers of all sizes in all industries in more than 140 countries. For more information on Dassault Systèmes’ solutions for the marine and offshore industry, visit https://ifwe.3ds.com/marine-offshore.

Login

Login