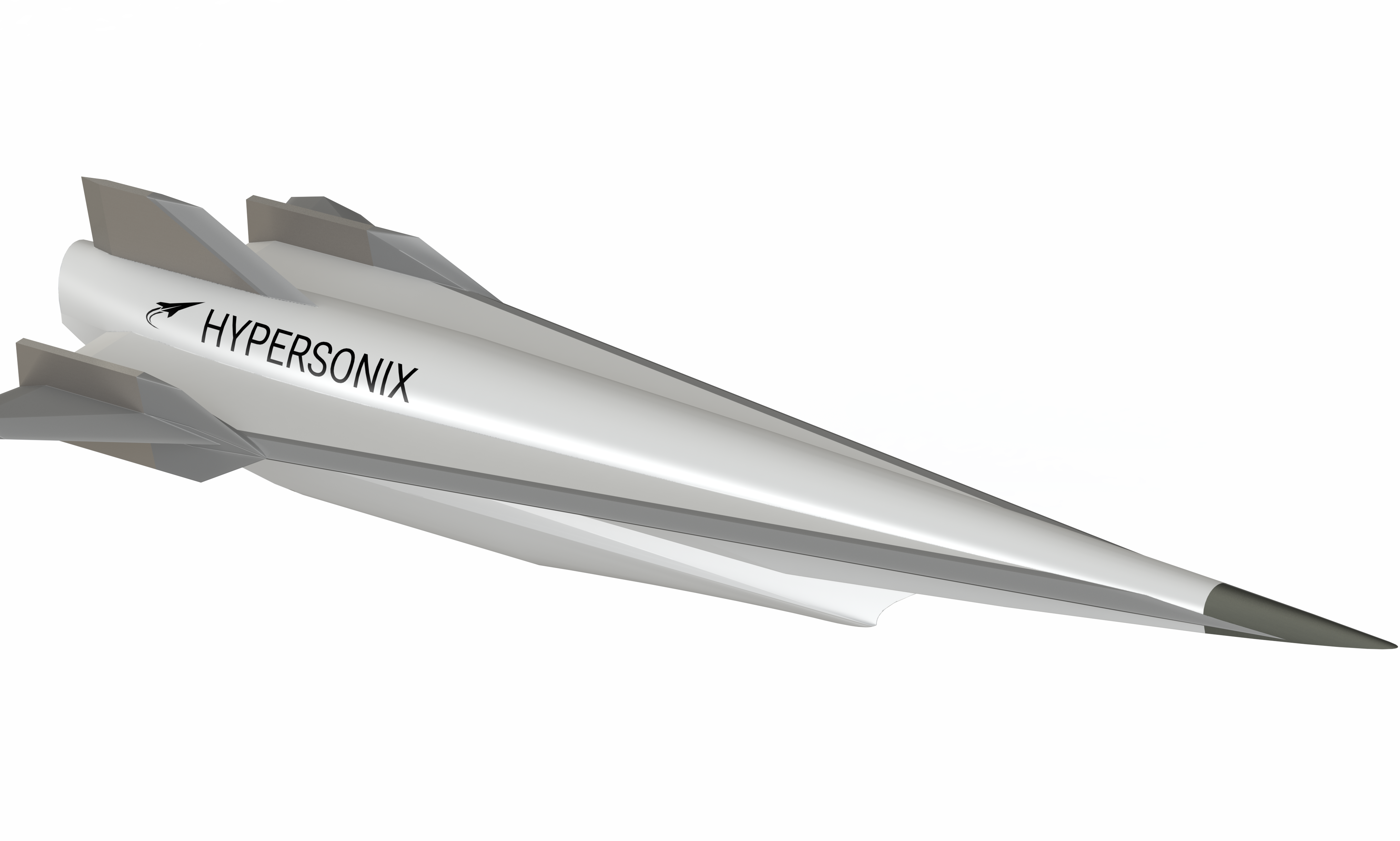

Hypersonix Launch Systems, the University of Southern Queensland, LSM Advanced Composites and Romar Engineering were awarded the grant via the federal government’s Cooperative Research Centres Project (CRC-P) to help develop a reusable UAV that can travel up to Mach 12.

To continue reading the rest of this article, please log in.

Create free account to get unlimited news articles and more!

Titled ‘DART CMP Airframe – a reusable hypersonic platform’, the group is expected to develop a reusable unmanned aerial vehicle (UAV) powered by a SPARTAN hydrogen scramjet engine that travels speeds up to Mach 12, making the UAV hypersonic.

According to the University of Southern Queensland, the engines use oxygen from the surrounding atmosphere, which is forecasted to reduce the UAV’s weight by 60 per cent. The university further explained that creating new materials to withstand the immense heat will permit the UAV to be reused for future flights.

“AE stands for Additive Engineering and is the fully 3D printed version out of high temperature alloys that are already available in Australia,” David Waterhouse, managing director of Hypersonix, said.

“The type of high temperature composites we require for DART CMP are currently not available here, therefore there is an urgent need to develop these materials in Australia.

“We are thankful that the government acknowledged this gap and responded with accepting our application. We can’t wait to have these materials ready in mid 2025.”

It is hoped that success in the project will support the development of a new sovereign manufacturing industry for heat resistant materials.

Professor Peter Schubel, executive director of the University of Southern Queensland’s Institute for Advanced Engineering and Space Sciences, explained that the university will provide a range of hypersonics expertise to help the consortium.

“The University of Southern Queensland is applying its research expertise in the field of hypersonics and future materials to help realise an innovative mission," Professor Schubel said.

“Our role in the project will be to develop and test the prototype ultra-high temperature composite material needed.

“Our expertise in liquid moulding technologies, automated fibre placement, pultrusion and filament winding capabilities with exotic materials allows us to develop revolutionary structures.

“As an industry-focused research and technology organisation, we are committed to delivering real-world, large-scale solutions for our clients, utilising our extensive laboratories and manufacturing equipment.”

Throughout the manufacturing process, the companies explained that they will rely on additive manufacturing and 3D printing as much as possible, which will be spearheaded by Steve Milanoski of Romar Engineering.

[Related: Local start-up Hypersonix sets sights on zero-emission spaceplane]

Login

Login