“Industry has come from a background of they’ve had to pursue projects on a project-by-project basis, and the department has pretty much let contracts on a project-by-project basis without taking a broader view of developing an integrated and comprehensive industry base. There’s some great people in defence industry of course, but the leadership and the culture of the defence industry will have to mature somewhat to reflect this newfound national sovereign responsibility.”

To continue reading the rest of this article, please log in.

Create free account to get unlimited news articles and more!

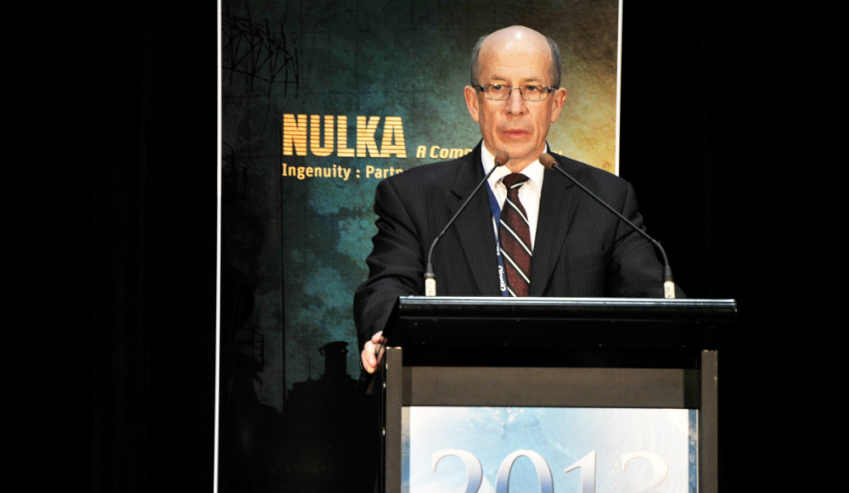

This week on the Defence Connect Podcast, former CEO of the Defence Materiel Organisation (DMO) and current chairman of Navantia Australia Warren King joins us to talk about his 50 years of experience within Defence and defence industry, and what Navantia has offered as key components of its SEA 5000 bid.

King takes us through his beginnings as a Navy apprentice, his time seconded to the US Navy, what he learned from working in an SME and his eventual rise to CEO of the DMO.

The chair of Northrop Grumman Australia’s advisory board offers his advice for those leaving the military, how Defence can achieve the most from its 2016 Defence White Paper ambitions and the need to grow leadership within defence industry.

Enjoy the podcast,

The Defence Connect team.

Listen to previous episodes of the Defence Connect podcast:

Episode 449: SPOTLIGHT: Leveraging AUKUS to build a credible submarine deterrence, with VADM (Ret’d) Dave Johnson

Episode 448: PODCAST: Assessing the region’s rapidly closing risk window, with Mike Pezzullo

Episode 447: PODCAST: Becoming the world’s most cyber-secure nation, with Cyber Security Minister Clare O’Neil

Episode 446: PODCAST: Local infrastructure – key to delivering Defence capabilities, with Cr Peter Hudson

Episode 445: PODCAST: A growing chorus calls for a national security strategy, with ANU’s Professor John Blaxland

Episode 444: PODCAST: Doing the rounds – the week that was in Defence and defence industry

Episode 443: PODCAST: Unpacking the history of Australia’s defence policy and posture, with Michael Pezzullo

Episode 442: PODCAST: Moving beyond the End of History

Episode 441: SPOTLIGHT: Unlocking Defence performance through infrastructure design, with HDR’s Tim Napper

Episode 440: PODCAST: US Space Force engages with Australian SMEs at AusSpace24

|

Announcer: |

Welcome to the Defence Connect podcast with your host Phil Tarrant.

|

|

Phil Tarrant: |

Good day, everyone. Welcome to the Defence Connect podcast. This is Phil Tarrant here, I'm your host. Going to have a bit of an interesting chat today. I have someone in the studio who is well versed with our defence industry having worked within it for many, many years, both within industry and also government. And also a former Navy man as well. So the conversation today is going to span, I think, around 40 plus years of defence and defence industry. I'd like to introduce Warren King into the studio. Warren wears a number of different hats, and I'm sure most of our listeners will be familiar with Warren. Currently chairman of Navantia Australia and member of the Northrop Grumman international advisory board. Probably you're very familiar with the name. Warren was formerly CEO of the DMO as well. Warren, how you going?

|

|

Warren King: |

Cool. Very well, thank you. Thank you very much for the invitation to be here.

|

|

Phil Tarrant: |

Well, thanks for coming. Did I get that right, 40 years? Or did I over extend that?

|

|

Warren King: |

Well, you're very generous. It's actually 50 last July. I don't like to say that, it just sounds a few too many.

|

|

Phil Tarrant: |

It does, but I think I'm quite fortunate to be able to, I guess, take a journey with you over the next half an hour or so to get your insights on a career in defence, and where we are today, which I think is a very ambitious and optimistic time for Australian defence industry, Australia as a whole. But looking back 50 years to what is a very different geopolitical landscape, what is a very different defence industry, what is a very different military we have today. So I guess starting back 50 years ago, you're a former Navy man, when did you join the service? Why'd you join?

|

|

Warren King: |

Previously I kept this just for family members, but I was actually invited to leave school in 1967 by the headmaster, who didn't feel that the school or I was advantaged by my continual presence at the school. And I'd really only completed year 10. So I joined the Navy as an apprentice. They had a scheme there, which after a certain period of time you could be selected, for a very select group, to go back to high school. And I did that inside the Navy. Then got selected to go university in the Naval College, and became an engineer in the Navy. So it was a great opportunity to reinvent myself, if you like, from a staggering start to my working life. But I would say this, Phil, that the background in doing trade training and learning to work with my hands, and what it takes to make something and make something well served me very well throughout my career.

|

|

Phil Tarrant: |

Do you think that opportunity still exists in today's Navy, or it's just changed a little?

|

|

Warren King: |

Yeah, I do. In fact, I even think it's probably going to be greater, Navy and the entire military. Unfortunately, because of limitations on the number of people in uniform the military don't do all the things they used to do, and that we'll come to this later I'm sure. But that makes it so important to have a very competent defence industry backing up the military. But, look, I would definitely encourage every young person with thinking about a military career to investigate it. There's no doubt to me that that formation years were fantastic in creating not just skills but an attitude to life which is unsurpassed, I think.

|

|

|

Having said that, one of the great joys of building our defence industry in the current policy of Australia, and developing that industry, means that people who are committed to the country but who don't necessarily want to serve in a military role have other options now to serve to country, or will have, as this industry grows. But to your key point, yeah, I would definitely encourage people that are thinking about it to consider a military career.

|

|

Phil Tarrant: |

We're producing some very good officers these days, but to look at your experience, you started on the tools and you transitioned into a career in engineering that spanned 20 years in the Navy. Do you think today's officers are lacking those real hands-on capabilities?

|

|

Warren King: |

Yes and no. Can I just touch on one point here that I'm quite passionate about, which is diversity? I think the introduction of females into the senior ranks and military ranks, all ranks, and all trade and all employment categories has added enormously to the professionalism of our military. I just can't stress enough how important that has been in creating this very, very balanced military force we have today. I really enjoyed serving with the people I served with when I was younger, and they were great people and very committed. But we were strictly male and strictly one sort of mindset.

|

|

|

When I go to a ship today, as I still get the chance to do occasionally, and I see these young professional crews I'm just so excited about what that diversity has done for developing the professionalism in our military. Now, when it comes back to industrial experience, I think it's true. Because we've had the rundown of the military numbers over the years they've had to concentrate much more on operating the highest degree possible the equipment assets they have. And because we've also changed from owning shipyards, for example in the case of the navy. Air Force no longer runs workshops to the extent that they used to. Army the same. That there has been a disconnect perhaps over the last 10 years from the military people and the industrial base.

|

|

|

One of the implications of the new policy of Australia to have a defence industry will be re-establishing the skills of the military people to both participate in and to manage that industrial base and to be a part of it. It is another element of the challenge that comes with this terrific new approach to defence industry.

|

|

Phil Tarrant: |

It's an interesting observation, it's an observation which obviously spans 50 years, so seeing that wholesale shift in the way in which the makeup of our military forces, and now the utility of those military forces, by having a very diverse and probably more sophisticated experience base, because we've got so many more people operating within it. But looking at that 50 years from today back to when you were in the Navy, the 20 years or so that you were serving, what's the best thing you ever did, you think? What are you most proud of?

|

|

Warren King: |

That's a good question. I'm not sure I can think back that far. Look, I was just very proud to be part of the Navy. I think we made the best of what we had in those days. We did not have ships of a leading calibre. We took delivery of the new, then, DDGs, which really lifted our ability to seriously participate. That was very good. I trained in UK for a while, and that gave me more of an international dimension. Probably the two most interesting jobs: the first I was seconded to the US Navy to assist in developing the FFG-7 class combat system, and actually worked as a member of the US Navy. So ironically I found myself being part of the delivery team of delivering three FFG's to Australia. So even though I was an Australian I was delivering those ships to Australia as part of the US team.

|

|

|

What was fascinating about that, it gave me an insight into the complexities of ship building. Those ships were built to a common design in three shipyards. And managing cost control, managing schedule, managing budget, more than 50 ships built. This gave us a real insight, gave me a real insight, into what it takes to control and manage a large shipbuilding program. It was an invaluable experience, and of course it also gave me an invaluable experience working with senior echelons of the US Navy and how decision-making works, and how it interplays with national politics and other matters. That was really a fabulous experience in the industrial aspect. At one stage in that programme, I'll just give you a sense of the scale, we were delivering a ship every 10 weeks. Now, obviously, it took a long time to build a ship, but that was a number of ships coming down through the production line, the combined effort of three yards.

|

|

|

The final one, I think, that really interested me, and still I've learned lessons from that, was my last job was running the engineering school for the Navy. I was sent there most reluctantly. I consider myself a frontline professional engineer, and what was I going to do going to a training establishment? The ability to play a role in shaping the training of the young people, both commissioned and non-commissioned, was very, very important to me. And I learned an awful lot about the importance of training, education, and in preparing people for a career.

|

|

|

I also learned a lot about human experience, to the point where we would get young people in ... And it wasn't just my school, but of course the recruit school and so on contributed to shaping these people. But on many occasions we got people in that were "lost". Didn't know where to go in life, the education system didn't work for them, they hadn't been terribly successful. And to see them change within 12 weeks at recruit school ... A year, say, with recruit school and technical training. And to see them have a new purpose and a new focus and confidence in themselves was a wonderful experience.

|

|

Phil Tarrant: |

So there's a point in time where you said it's time to leave the service and move into defence industry. And most of our listeners will be familiar with the work you've done at the DMO with the AWD and the Joint Strike Fighter. But there was a gap between leaving service and joining the DMO of 10-ish years where you were in defence industry. So what was the catalyst for you to get out of the uniform and move into defence industry and start working on the other side of the fence, I guess?

|

|

Warren King: |

Well, it was nearly 20 years, by the way.

|

|

Phil Tarrant: |

20 years.

|

|

Warren King: |

Nearly.

|

|

Phil Tarrant: |

Nearly 20 years.

|

|

Warren King: |

Not quite. There was two motivations. One was, probably not the major motivation, but I could never become the Chief of Navy. Now, it wasn't that I had career ambitions or thought that I was the anointed one, it just seemed to me that since I could never become the head of that organisation, because I didn't have an operational background, that I needed to make sure I had maximised all my opportunities in other ways. The second thing was that the military career was fabulous in terms of building structures around you, support, mateship, all of those things, but I didn't know whether I could survive without it. And I had ambitions to see if I could survive without all those wonderful structures around me, so I actually went to an SME. And the company was only 16 people strong when I went to it, so it was a real SME.

|

|

Phil Tarrant: |

So was it quite daunting when you stepped into the office on that first day outside of the navy and as an SME? Did you remember the feeling or the sentiments back then?

|

|

Warren King: |

I do. I was both excited and ... We had two young children. In my Navy career when I indicated that I was going to leave I had senior people contact me and saying, "But you're going to be on a terrific career path", and all that. So I'd stepped out of what was a pretty good and exciting career path into something that had I no foundation in at all, but it was an exciting opportunity. But the first thing that came home, and one of the lessons I used to try and relay to people in the DMO, was an invoice hadn't been paid, a significant invoice hadn't been paid, and so on my first payday in industry it looked like we wouldn't have enough money to make payroll. And I can tell you, having got paid every fortnight religiously without any doubt-

|

|

Phil Tarrant: |

You know where the money comes from.

|

|

Warren King: |

Suddenly realising, "Wow, what are we going to do if I don't get paid?" That was really a grounding experience, and one that I'd encourage people that had a long public service career to imagine what it's like. And the reason I hadn't been paid was someone hadn't gotten around to it. Now, I think by the way, the government's gone a long way to correcting that sort of things that used to happen then. But that certainly did ground me. And immediately we were thrown in some very difficult contract negotiations, and I realised straight away that you had to live a lot more on your wit.

|

|

|

And one of the great things about being in the military, and I don't say this in any derogatory manner, is people in the military commit their being to looking after the good of the nation. I say that in a very genuine way. They give up lots of freedom, lots of flexibility in order to commit to provide a defence for our nation. In return, however, they get lots of structures around them, which are very good structures. In fact, it's still interesting to me, you can go anywhere in the world pretty much, even if you haven't seen the uniform of that country before, and walk into a room and just about know who they are, where they are, what they do, where they are in the pecking order. Even going to a table for negotiations is interesting, because when you go to a discussion with a military group of people they all know just by looking around the room who's who. Who's going to run it, who's got the last say.

|

|

|

When you go to industry, of course, that ragtag guy sitting over in the corner who hasn't said anything all meeting might well have the banker call. So learning to read people, learning to read how you manage power, how you get an outcome, how you negotiate, what strengths you have, what strengths you don't have, they were great lessons. And being an SME is rather interesting, because I've worked now for a number of multinationals. When you work for a multinational, of course, you go in with a badge with that multinational. Even if you haven't worked for that company ever before, the day you put on the badge of, let's say in my case, Northrop Grumman you're a Northrop Grumman. You inherit all the values of that country, all the strengths and so on, so when you go to a meeting you come in with that pedigree.

|

|

Phil Tarrant: |

Pedigree.

|

|

Warren King: |

It's the same with the military. Now, I understand, I think, because I spent about 12 years with SMEs, when you're an SME you don't have that either. So you don't have the leadership role, you don't have any sort of badge of authority, and you've got to make your way in life. And it's tough, it's really tough for SMEs. And I may not have been successful in my time in DMO, but I tried very hard to inculcate people in the DMO with some of the challenges for SMEs.

|

|

|

Now, they're not always perfect, SMEs can get a bit carried away sometimes with some of their enthusiasms, but nevertheless it is true that they work from the hardest domain to establish themselves, keeping a cash positive position to keep building their business, taking quite often great personal risks. And that's a great training ground. I don't think I actually ... Well, I did. I had been offered jobs with multinationals when I indicated I was going to leave defence. But I had chosen, "Let's go to an SME and see what life is like."

|

|

Phil Tarrant: |

What the real world's like.

|

|

Warren King: |

Yeah.

|

|

Phil Tarrant: |

A lot of our listeners on the Defence Connect podcast are either currently uniform or they're thinking of exiting uniform into the corporate world. And obviously, you spoke about it beforehand, defence industry offers all Australians an opportunity to contribute to the national security. If you had one tip for people looking to transition from uniform into defence industry, based on your experience, what would it be?

|

|

Warren King: |

I'll probably give you two. But my first tip would be, don't leave because you're ticked off, I'll use the soft word, with the service you're in. It won't be the right reason. If you're just ticked off with the Navy, Army, or Air Force, the chances are that you will transfer out for the wrong reasons. And you won't have analysed properly what it means to be in defence industry. I'd strongly encourage that person to think about why you're getting out, what is it? In my case, it was to see if I could stand alone, to see if I could make a difference. All those sort of things. But it wasn't because I was unhappy with the Navy. In fact, I loved the navy. I still do. So have a positive focus, not a, "You know, I'm sick of this mob." It's a bit like out of the "frying pan, into the fire".

|

|

Phil Tarrant: |

So just a very-.

|

|

Warren King: |

"I don't like being in here, I'm going to jump out." So don't do it that for that reason. That would be my first point.

|

|

Phil Tarrant: |

Good point.

|

|

Warren King: |

I've seen a lot of people fail when they've left the military, thinking that's ... And I've outlined in the past why it's so good in the military, all the support you get, the camaraderie, and mateship, it's fantastic. The second thing is, when you get out be prepared to build another career. You are going to have to have, in the main, a different set of skills. You're going to have to present the skills you have but use them in a different light, or grow them into a different place. Sometimes a lot of people will get offered jobs, particularly as they get to be more senior, because of what they know ... Sorry, who they know, the connections they have, etc. And that's only going to be good for two or three years max.

|

|

|

So if you're going to get out, you're going to accept a job from a company, accept a job that builds a new career for you. And even if it's a step back in pay or a step back in "rank". But if it leads to a place, if they're investing in you, or putting you in a job that takes you to a place where you want to be, then think very carefully about that job.

|

|

Phil Tarrant: |

Do you think your time within defence industry, subsequent to your service, give you the right preparation to shift into a role with DMO? You know, you ended up running the DMO as CEO and you had other roles within that prior to that. Was it a good enough apprenticeship, do you think, to put you into the role where you start sitting on making the decisions around procurement rather than being one of the facilitators of that procurement?

|

|

Warren King: |

Yeah, I'm pretty sure it did, because by that stage I'd served on a number of ships, seen the deficiencies in the ships we had in those days, and the strengths when we got some newer ships, so I understood it pretty well from being in operational environment. I think I spent, I can't remember, six or eight years in ships at sea, so I had a long stretch at that, including some long deployments. So I had a pretty good sense of what it was if the ship wasn't designed properly, and a good sense of what it was if we couldn't get it maintained well, or couldn't get parts and so on. That was good exposure.

|

|

|

The industrial side, just before I went into DMO I was encouraged to apply for a job. I then moved to a multinational, Raytheon, and I got the experience there of working with a large, effective multinational defence company. And that I think was probably the icing on the cake, to use an expression, where I balanced out now what it was like to grind away. When I did tenders in the SME it was all of us, we wrote the words, we did the drawings, we cut off preparing for it a week out and then started printing and collating and everything else.

|

|

|

Of course, the great value about going for the multinational then was how to deal with international boards, how to deal with members at a company that may not understand Australia. And this is not specifically about Raytheon. In fact, they were incredibly successful during that period that I was in there with that team. I think, from memory, the team grew from something like 40 or 50 people to way over a thousand in four years.

|

|

Phil Tarrant: |

Good growth.

|

|

Warren King: |

Very successful building up of that capability. But learning how when you're in a multinational it's much more about not just what effort you personally give, which you have to do, but also how do you manage teams, and how do you deal with the offshore company, who obviously have fiscal responsibilities, who have their approach to life. And how do you bring them together, how do you make sure that their focus, the in-country team's focus and the national interest here in Australia, are all well served? That was a particularly useful period of time for me to understand big corporations and the things that challenge big corporations.

|

|

Phil Tarrant: |

I want to have a chat about your time with procurement arm of the DMO. But prior to that I think maybe a good way to set this up is, we've reflected on 50 years of your career in defence and defence industry and where we are today versus where we were back in the 60s. There's some major coming online, new subs, new frigates, new land vehicles, there's a lot happening in defence at the moment. Where we are today versus where we've come from. If you were going to try to explain or give context to this moment in time with defence industry and for defence industry participants, what would it be?

|

|

Warren King: |

We've never seen this before, ever. And we're never likely to see it again, or any time soon, unless we all deliver. And delivering means everything. It means focusing on the customer, focusing on getting your product out, focusing on the national implications. And we have this opportunity in Defence and the defence industry the likes we haven't seen since federation, ever. We've had a response during world wars with industrial armaments, development companies, building rifles and ammunition and stuff. I don't want to diminish that at all, but that's been in response to a real and immediate threat. This is a far bigger objective in the sense that not only we're just doing the immediate consumables response, but we're building an industry.

|

|

|

Now, the taxpayers got a lot of places that they want money spent, hospitals, trains, police forces, whatever. There's billions going into our industry over the next 10 or 20 years, billions. And unless the leadership of the defence industry is totally focused on delivering in the total national interest ... I mean, clearly they have to look after the company interest, their obligation is to the shareholder without a doubt. We all know that, we all know our fiduciary responsibilities. But sitting behind all that has to be a total commitment to the establishment of the security of this nation, the support of our military, and the establishment of this industry. And if the taxpayer doesn't believe that's being developed, within three to six years it could all come crashing down. It can come down that quickly.

|

|

|

So there's no time to be wasted, there's no opportunity for failed projects, there's no opportunity not to be totally committed and understand what it takes to make ourselves successful. There's just no opportunity to do that. But don't think that I'm worried or anything, I'm just simply saying this is the best opportunity we ever had. We need true leadership from defence industry to respond to it.

|

|

Phil Tarrant: |

Where can we be unstuck or get unstuck then? Do you think the leadership is there at the moment?

|

|

Warren King: |

I think it's got to grow a little. You can't blame industry for that, it's been opportunistic. And I make myself part of all of this because I've been around for that time. We have at least for the last 10 to 15 years progressed projects as projects, stand-alone one-off projects. So teams assembled, they chased a project, they won it, and then they almost choked it. Like the goose that laid the golden egg, right, because they just kept trying to get golden eggs out of that one project.

|

|

|

Industry has come from a background of they've had to pursue projects on a project by project basis, and the department has pretty much let contracts on a project by project basis without taking a broader view of developing an integrated and comprehensive industry base. There's some great people in defence industry of course, but the leadership and the culture of the defence industry will have to mature somewhat to reflect this newfound national sovereign responsibility.

|

|

Phil Tarrant: |

I was going to ask you that question, these major programs, particularly shipbuilding, the subs and frigates to be built, whether we've got the right people to build them at the moment, that's a different question, we'll get to that. But what's your definition of sovereign capability, and how does that fit within a context of this opportunity in front of us right now that you outline in terms of the long-term development of our own forces for the security of the nation in the decades ahead?

|

|

Warren King: |

Yeah, sure. Well, it goes without saying that ... And I can give you both my personal view and also Navantia's approach to that, and you'd probably expect me to do so. But sovereign capability can be defined in the first instance simply ... Or not simply, but comprehensively in the skills that are required to be able to design, develop, produce, test, and deliver surface combatants. That's what the continuous shipbuilding program is looking for. That's a given. Everybody will need to comply with that total capability. Now, you can't have that total capability day one. It has to be a program to identify all those capabilities, which I'm sure we all have as tenderers, and then put in place a practical program to build every one of those areas up so that at some point during the programme all of that resides in Australia.

|

|

|

I think there's a second element, and it's the one that as chairman of Navantia I've been very pleased to be part of offering, is sovereign ownership. We certainly focused on a sovereign capability, but we've also offered in our tender to create a sovereign-owned capability. And I see that as a wonderful thing. For example, we've offered the ability for maybe industry superannuation funds to take a role in it so that the workforce sees a genuine interest in not just getting a job on a day-to-day basis, but that the industry is sound and ongoing for long-term.

|

|

|

We've also offered the government, and we haven't been prescriptive, to work with us to decide if they want, say, other industrial partners. Or whether they'd like to put in an IPO [initial public offering], for example. All of these things we think are important, but we don't want to offer it in unison of a coordinated approach with both the government and the department. Because, of course, in doing that you've got to manage with the support that you need from offshore, from your design teams, from all those other people that have got experience. You don't want to just cut it loose, you want to develop it. And when it's in a mature state, and when it's at what the nation wants, then implement the next phase. For me, sovereignty is established capability, and the ability to have Australian ownership.

|

|

Phil Tarrant: |

Two of the major announcements this year will be LAND 400 Phase 2 combat vehicles, so we'll see what happens. The other one, you've alluded to it, is the SEA 5000 Future Frigates tender. Which I'm sure you know the date probably better than I do, probably April or May this year we'll get a decision on the successful tenderer. Obviously, Fincantieri, Navantia, and BAE look set to secure this major program. I guess the closest experience we might have to shipbuilding at the moment is the work that's been going on with AWD, the Hobart class destroyer, of which you're very familiar with. And I know our listeners will be very familiar with some of the challenges associated with that, lessons learned.

|

|

|

I'm quite keen on your observations of that particular program. But rather than get into the nitty-gritty of what went wrong, I'd like to look at what we can learn, you personally, and what Navantia can take from that, through that shipbuilding process, and how can that be transitioned into a successful SEA 5000 program? Whether that's Navantia or not.

|

|

Warren King: |

Yeah, or anybody. Sure. Look, the two fundamental lessons from Air Warfare Destroyer, I feel, are the contracting management model and how quickly skill sets atrophy. So if we come back to the contracting model, we had previously had perceived problems with the Collins-class submarines, and the Department of Finance had put out a study to a merchant banking group, Carnegie Wylie, to look at what would be a better contracting model than prime contractorship. And the model that was very in vogue at the time was alliance contracting, and so when I joined the department I got a few files of studies about what ship might work, some early decisions on some other matters, and that we would be completing the program under an alliance contract.

|

|

|

Now, my experience had been much more "you have a prime contractor", so I did ask the question. But this is the nature of national business, the decision had been made. I don't think alliance contracting had been tested really at that stage. There was a lot of enthusiasm for it. And so we set up an alliance contract. Now, it might well have worked better than it did in a general domain of contracting. And the reason is this: basically the theory is that if you've got a share of work and there's a better way to do the work which reduces your share but increases your profit then you'll do it, right?

|

|

|

And this is all very well. So let's say we're going to make a civil construction, a building, steel and concrete. And the steel and concrete supplier form an alliance. And the concrete supplier comes up with a way to halve the amount of steel, but everybody gets a better profit. Well, they'll probably do it because the steelmaker's still making steel for a thousand other sites as well, not just that one site. The problem in alliance contracting in the defence environment, it's much more complicated. The shipbuilder is the shipbuilder, they own everything about that ship, and all the combat system integrator, and so on. So that adds a complication, because how can the shipbuilder give up shipbuilding, you know what I mean, because that's his one job they have.

|

|

|

The second complication was that the designer, that was Navantia, only had about, would have been, a tenth of the work that the shipbuilder and the combat system integrator, Raytheon, had. Not even a tenth. They believed at that time they had a proven design, which they did, and so why would they put at risk ... In terms of the total profit share of the project, 1% let's say. Why would they put that at risk against the other two big players who'd had so much more work, so much more influence? At that time Navantia had said there's no commercial sense to be part of the alliance, and that was a fundamental flaw.

|

|

|

I thought we'd overcome it by the way we'd contracted them, but in reality if you don't have the designer ... A designer sounds a bit hands-off, "I just do a design, I walk away." But actually, in shipbuilding the designers actually know how to make their product, so they're more than just the designers. They are actually the intellect in how to build the product. So that was a really powerful lesson, and I think you can see that in SEA 5000. The department is going down the prime contractor model, basically led by the designer. And I just fully support that approach.

|

|

|

The second thing that we learned, which is really, really critical for SEA 5000, is that it would only been a couple of years since the last Anzac had been built, so I had assumed that the residual skills and knowledge ... And by that, I don't mean the people that just weld ... I don't mean "just weld". I don't mean the people whose job is to weld, or people who run electrical wiring. But the blue-collar foreman, the supervisors, their skills had left the industry as well. And so in reality it's not that difficult to get really good welders in Australia, really good tradespeople. They are there and we can build more. They've always come through, in Collins and other places. Our tradespeople have always come through. What's failed us over and over again is middle to senior management, who either don't have the skills or don't have the background to effectively manage that workforce, and let them do their job well.

|

|

|

So they'd be the two fundamental lessons. The first one, I think is addressed. SEA 5000 is being executed under a prime contract model. Fully support that. And the second one is, let's start work on the Future Frigate as soon as we can, because of course the Hobart class construction is running down and the numbers of people are dropping off. I would very much like to see it started just as soon as possible.

|

|

Phil Tarrant: |

The Cabinet papers for 1994/95 were released at the start of this month in Jan, and they were talking about the Anzac class, key learnings from that. And we did some stories on Defence Connect around what that means for the successful SEA 5000 tenderer. One of the key problems was, I guess, the speed of getting those ships to market and not having enough skilled people to actually do the welding and running the wires and stuff. So in terms of the context of the Navantia bid as part of the competition to win SEA 5000, what would Navantia be doing to make sure that they can run a program on time, on budget? And a lot of that's based on the ability of people to actually deliver. So how you going to find these welders, these workers?

|

|

Warren King: |

If I can give you a bit of context to this first it might help. So, you would probably recall that as the Air Warfare Destroyer project ran into some troubles Navantia was contracted by the Department of Finance to manage the work on the Air Warfare Destroyers, manage and assist ASC in completing the Air Warfare Destroyers. So we now have a management team in ASC, we work in unison with ASC, and as part of that involvement we can say that since we've reset the Air Warfare Destroyer with that additional skills and learning that have come into the air warfare destroyer project not a single schedule has been exceeded, nor a single budget. So we know the workforce in Adelaide absolutely intimately, and we have worked with them now for, I think, going on close to two years.

|

|

|

So based on that detailed knowledge of the workforce that's there, and the detailed knowledge of the skills we'll need to start up the project, we have a complete executable program to start SEA 5000. Now, it's trade by trade, it's skill by skill, but it's not just trade people. It's also, as I mentioned, supervisors, foremen, planners, supply chain management. These are difficult concepts to get across if you've never worked in this sort of industry before. But if you say "supply chain management" it sounds quite simple, but it's very complex. You've got to find the supplier, you've got to go through all the due diligence with the supplier, you've got to make sure that they're qualified, that they can build parts to the right standard repeatedly, all of this sort of stuff.

|

|

|

Well, the benefit I see of our particular offer is a lot of that, not all of it, but a lot of that supply chain is in place. We've been building these ships. One thing I would like to touch on. I'm sorry to do your interviewing for you.

|

|

Phil Tarrant: |

No problem. You can ask me some questions if you want to.

|

|

Warren King: |

You mentioned the lessons learned about Air Warfare Destroyer, they're not all negative.

|

|

Phil Tarrant: |

There's positive lessons.

|

|

Warren King: |

There's some huge positives. I spoke to the commanding officer of the first ship, HMAS Hobart, recently, and he was glowing in the performance of the ship.

|

|

Phil Tarrant: |

So he's happy?

|

|

Warren King: |

Well, that's what he told me, and I don't think I'd any reason ... What I hear is he's telling everybody that will listen. We've only put aside, for the trials program, very short periods of trials. And guess what? All the trials were achieved in those ... If you went back 20 years ago and you were talking about Collins or something it was always about system integration and "systems don't work" and "this doesn't work". Have you heard one bad word about Hobart? And it's got the most sophisticated combat system that we've ever fielded in Australia. Raytheon managed the integration of that. The most sophisticated system we've ever had fielded in the Australian Navy, and it's just gone swimmingly.

|

|

|

Now, will we run into a couple of problems in the future? Possibly. But have we got any fundamental problems on the Hobart class? None. The ship's performing exceptionally well. So, yes, there were some management issues. Yes, we didn't meet the schedule, we should've. We should've had better focus on certain areas. But have we got a fabulous ship? We certainly have.

|

|

Phil Tarrant: |

And this experience over the AWD program ... It's working at the moment, in terms of the build. What sort of confidence do you have moving into this April/May period? It's a fierce competition for SEA 5000. What do you think? If the decision is a Navantia decision, why do you think they'll choose the Navantia option?

|

|

Warren King: |

Phil, I've got to say, eventually it's up to government and the department. I'm supposed to be retired. I'm working for Navantia because I believe they're the right solution. So I can outline why I believe they're the right solution. I think I touched on this earlier. We can't afford to have a failed project in the defence industry because the taxpayers will be sorely disappointed. And future governments have got to be responsive to what the general population feels.

|

|

|

So unless we have a project that absolutely executes flawlessly, so that the people of Australia build up a real confidence ... Remember, this is the first time we've played with a real sovereign defence industry. Not just building up to build a few ships, but a sovereign industry. Unless that executes flawlessly, and by that I mean absolutely on budget, absolutely on schedule, absolutely to the capability offered, unless that happens, the people will walk away from it. And I don't blame them. They'll say, "What are we putting money into this industry for?"

|

|

|

So having said that as my premise for my basis, for the recommendation, then it's as simple as this: we've built three of these ships. You can tell the level of sophistication of a shipyard by the amount of fit-out as a ship, as it goes. So the best way you get production efficiency, obviously learning from building the first ones. Bit like doing IKEA at home. I don't know if you struggle with that, but I have.

|

|

Phil Tarrant: |

It gets easier after the third one.

|

|

Warren King: |

By the time you do the shelves, you realise you've put them back on before you put the front on, or something, whatever you should've done. But by the time you build the second set it's just a breeze, right? So there's that element as well. Secondly, we've got the experienced management team here now, that's helping. And then thirdly, the amount of fit-out you do before you bring the blocks together, the modules together, creates the efficiency. There's a 1/3/8 rule, a job that takes you one hour in the block ... So when the block is just stand-alone in the workshop, is one hour. If you do it when it's consolidated in the ship, the block is in the ship, but the block is on the hard stand, it's three hours. And if you have to do that same job when it's in the water, it's eight hours. That's the industry rule.

|

|

Phil Tarrant: |

Broad brush strokes, yeah.

|

|

Warren King: |

So what you've got to do is get as much done in the ship as you can before you start bringing them together. Now, to do that, of course, is you've got to have a lot of knowledge and know very well what it is you've got to do. Well, we've seen that improve on every ship from Hobart, Brisbane, to Sydney. And so the ships are actually coming forward now. Far from seeing any further delays, there's actually this embarrassment almost that the third ship is creeping into the second ship because we're making such great progress over there in South Australia.

|

|

|

There's really a huge number of positives. We've got experienced team. We've got experienced team on the combat system. We've got experienced group of workers in Adelaide. We've got an experienced shipbuilding designer and manager in Navantia. And the design for our F5000 is about 80% done. The completion of the design is a key determinant on the efficiency and the build. Plus we've got the Australian supply chain. And I just don't want it to go wrong.

|

|

|

I'll retire sometime soon, some people say I never will, but I will. But not soon soon, but at some point. And I'd love to retire knowing that we've launched onto this project, that it's absolutely going to execute. That we absolutely have the confidence of the Australian people. And that mums and dads start talking about, "Have you thought about going into shipbuilding industry?" Because as I said earlier, a lot of people won't want to be in the military, but they love the country and they love the notion of working for the country, even if it's in an indirect manner.

|

|

Phil Tarrant: |

Just on the Australian supply chain, I think subsequent to the 1180 OBV decision all of the three tenderers for SEA 5000 have re-engaged discussions with ASC as part of the shipbuilding programme. Where's Navantia at with-

|

|

Warren King: |

We've never not been discussing with ASC, or Austal, for that matter.

|

|

Phil Tarrant: |

Okay. You've mentioned beforehand the mum and dad Australians encouraging their sons and daughters for looking for a career in defence industry. You signed an agreement late last year, I think it was TAFE SA and the Welding Technology Institute of Australia, obviously in preparation for creating our next generation of welders and skilled tradespeople. Funnily enough, it was one of the most shared stories we've had on Defence Connect for some reason. So it resonated with certain people. Where are you sitting with that at the moment? Is it still developing?

|

|

Warren King: |

It's still developing. I mean, this is intensive periods now. And, frankly, you get to the point in a tender process where it's in the government's hands and the next steps really rely you to be either endorsed as the contractor or not. Because industry's ready, they're poised, education organisations are ready and poised, but it's getting very close to that time where we need to know the answer. The nation needs to know the answer. I'm not trying to rush government or the department, but the next steps depend very much on materialising all the agreements, all the visions you've got.

|

|

|

All of our visions, in my opinion, are executable, practical. We've looked at the number of people we have to recruit, the number of each trade we have to train. We've done a very detailed analysis. We've built up good links to all the different organisations that we will need to join us on this venture. That's not to say there won't be more or others. We've run roadshows around Australia, we're also doing one-on-ones. So I think it's just a ... We're ready.

|

|

Phil Tarrant: |

You're ready.

|

|

Warren King: |

We've got the plan, and it's executable. That's a big thing. It's not just a plan, it's got to be executable. You can't have a plan that says, "I'm going to recruit and have a thousand welders in a week." That's not a plan, that's just idle chatter. It's got to be executable within the bounds of what exists, or what you can bring into bear.

|

|

Phil Tarrant: |

And, obviously, I'll never have the opportunity to do this, but if I was a fly on a wall in a Navantia Australia boardroom, or even at corporate HQ OS, what's the feeling of the senior execs about SEA 5000? You quietly confident? Is there anything in particular that ... Fierce competition, good competition. Where's the head space right now?

|

|

Warren King: |

It's fierce competition. I mean, it's three very good companies, and I'm not for one second going to say anything else but that. And you'd expect Australia to have picked potential partners that are capable, competent.

|

|

Phil Tarrant: |

Absolutely.

|

|

Warren King: |

So if I heard one word that said "quietly confident" I'd take that person aside and give them the benefit of my, as you said, 50 years experience, which would be, "Wipe that off your mind", because you can't say that. It's a bit like studying for university degree and university exam, you never know when you've done enough. There's no, "Yeah, that's it, I'm home." We've got to keep focusing, keep thinking about all the things we can do to make this a successful project, and we're continuing to do it.

|

|

|

When it comes to rating ourselves, we've got an offer, it's built around some certain themes that we've touched on today. Others will have other themes that they're going to offer. It's very much up to the department and the government to think their way through those various options and come up with answer. Clearly, I'll go into my man cave for about three years if we lose, but hopefully there'll be a celebration. I think the one thing that's encouraging me though, if that's what you're wondering, is we're now the only company competing for SEA 500 that's also competing for the Canadian ship programme.

|

|

Phil Tarrant: |

I was going to ask you that question.

|

|

Warren King: |

And the US program. So that makes us in a unique position where it is possible that the Hobart class will actually be a common class in the Pacific being operated by Canada, the USA, and Australia, and would be a 50 plus ship class. So if those countries are interested in us, I'm sort of thinking, "Well, you know, there's something good about what we're doing."

|

|

Phil Tarrant: |

As we get closer to the decision, and maybe subsequent decision, we'll have to get you back on and get your observations, see where we're at. We have to wind up Warren, but just beforehand I just want to touch on the work you do with Northrop at the moment.

|

|

Warren King: |

Sure.

|

|

Phil Tarrant: |

I had a really good chat with Ian Irving, CEO Northrop Australia. I think it was about middle of last year, July time. So go and check it out, it's on defenceconnect.com.au. He was talking about the rapid growth of Northrop within Australia through acquisition and organic. You're sitting on the advisory board there. What's your input? What are you working on?

|

|

Warren King: |

Look, it's a fantastic opportunity. I've only chosen to do two highly committed jobs post-DMO. One is chairman, which is a fiduciary chairman. I'm the chairman of Navantia Australia, with four fiduciary responsibilities. On the Northrop Grumman side I was approached by Mr. Wes Bush, the head of Northrop Grumman in the States, to say, "Look, we want to be global, we know we're not as big as we want to be. It's a plan that we have." Because of some of my experiences, and I've worked a lot internationally. I've worked with a lot of European companies, American. I worked in the Pentagon, and I've worked in UK. I started a factory, in fact, in the UK, one of my jobs. "Would you help us? Would you be on an international advisory board to help us with what it's like to grow internationally?"

|

|

|

The reason I supported Navantia is I believe that ship is the right ship for Australia. The reason I took on the job with Northrop Grumman is because I think Northrop Grumman internationally is under-represented against all the things that they do in America. We've got the presence of the other multinationals and it's pretty strong. But Northrop Grumman has so much equipment, so much talent, so many skills, system integration, it's not well recognised for it in Australia, and indeed in Europe. And I believe that if you're going to have a strong defence, a stronger defence industry, then you need companies like Northrop Grumman well represented, and the customer being aware just what they can bring.

|

|

|

That's why I took on that job. I love it. I guess my big theme with discussions, with the senior management of Northrop Grumman ... So I'm on the international advisory board, I'm also chairman of the Northrop Grumman Australia advisory board as part of that role. And we'll be bringing on a few more members. It really hinges around the difference between trading globally and being a global company. And there's quite a big difference. To be a global company you have to be in the tapestry of that company. You have to be, what I call, being part of the fabric. And we're working on that.

|

|

|

We've made some really big progress in that area. We've made some great progress on the work we're already doing here in that area in Australia. And, of course, we've got a couple of really big opportunities coming up. Triton decision should be sometime early this year. And a number of other areas that we think we've got some fabulous skills in the US that we really want to bring into here. And I'm also delighted to be working internationally because it's a bigger role, but it's also a role that lets us work perhaps more closely with UK and our UK partners, and also very much into Japan and Korea as part of being a strong group in the Asia-Pacific region. Very exciting job. Fabulous company. We just need to beat our drum a bit more, I think, and let people know what we can really do. It's a great company with some great, great people.

|

|

Phil Tarrant: |

That's good. Warren, I think we've done a reasonable effort at looking at your 50 years of defence and defence industry, but we've only just touched the surface. But I really appreciate your frankness and you sharing your view of the world. And I completely agree with you that it's not just a generational opportunity that we're in right now. It is, to your point, since federation we've never been in this situation right now where we can truly look to equip our nation's security in the years ahead through some very smart acquisition. But also mobilising a very talented workforce we have in Australia to contribute to the greater good of the nation by helping building these assets.

|

|

|

Thanks for coming on. We'll have to get you back in as well. And stay in touch and let us know what you're doing both on the Navantia side and also the Northrop side. I watch with interest these major programme announcements that's happening. I'm quite privileged in that I get to chat with all three tenderers, probably having a conversation which they normally wouldn't have with each other or other partners. For me, the jury's out, I have no idea where it's going to go. And to echo your point, three very strong bidders, and I'm sure our government will make the right decision. Thanks for joining me today.

|

|

Warren King: |

Well, thank you for the opportunity. And, look, clearly we're focused on winning, but if I could just leave encouragement for everybody in the industry, we really need to deliver now, whichever way it goes. Great opportunity and an exciting time. Thank you for the opportunity.

|

|

Phil Tarrant: |

Thank you. And remember to check out defenceconnect.com.au. If you're not yet subscribing to our morning market intelligence newsletter, please do. Be the first to know what's happening in defence and defence industry. It's defenceconnect.com.au/subscribe. If you like to get your information via social media, just search "defence connect" on LinkedIn, Facebook, Instagram, all that sort of stuff, you will track us down. And any questions for myself, the team here, or even Warren, you can email us,

|

Login

Login