Elexon Electronics has invested a further $1.9m in developing its state-of-the-art Industry 4.0 defence and aerospace manufacturing facility by securing a Sovereign Industrial Capability Priority (SICP) grant.

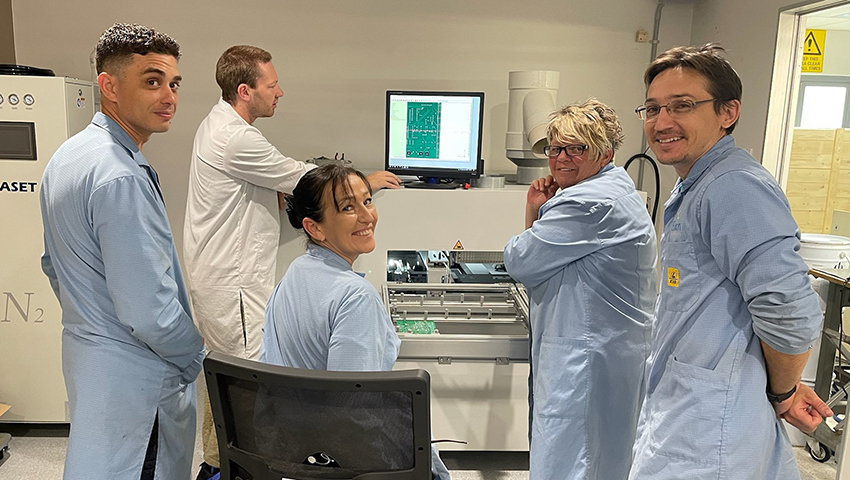

Innovative Australian electronics manufacturer, Elexon Electronics, has enhanced its manufacturing capabilities, procuring six new state-of-the-art machines for its Industry 4.0 manufacturing facility as part of its defence-readiness program.

Automation and interconnectedness have been the primary goals for Elexon, in developing its world-class Industry 4.0 manufacturing facility, offering unparalleled precision and manufacturing standards.

Over the past 16 years, Elexon Electronics has established itself as a global electronics player, pioneering various highly innovative and commercially successful products for a range of industries such as mining, pathology, automotive and recently defence.

The leading difference for Elexon, is its ability to design, engineer, prototype, test and manufacture complex electronics in-house, from high-precision custom PCB boards assembly to software and final assembly.

Today, Elexon is a trusted supplier of electronics for world-class companies such as Rio Tinto, Newcrest, Volvo, Aurizon, Aim Lab, Agilent and EM Solutions.

Defence-readiness investment

Elexon Electronics has spent the past year working tirelessly on its Defence-readiness plan, consisting of four key areas; Cyber Security Uplift, Quality and Management Systems, Team development & upskilling and Manufacturing Equipment Upgrades.

In order to become a valued Defence supplier, Elexon Electronics was committed to ensuring its quality and security systems exceeded industry standards.

Following engagement with the Centre for Defence Industry Capability (CDIC), Elexon received government support for its Cyber Security Uplift, ISO 14001 and AS 9100D management standards installations.

The successful implementation of environmental management standards ISO 14001 and aerospace quality standards AS 9100D involved also Elexon upgrading its physical and cyber security to protect IP - both Elexon’s and that of trusted Defence partners.

Government support, in the form of firstly, the “Made in Queensland” grant 3 years ago and lately, the SICP grant, allowed Elexon to invest almost $4 million to significantly increase its design, prototyping and manufacturing capability, with a strong focus placed on Industry 4.0 interconnectedness and automation.

The early procurement of high-precision automated surface-mount technology (SMT) equipment from leading European producers allows intelligent material handling, solder paste jetting, vacuum vapour phase soldering and X-Ray inspection.

More recent procurement of intelligent production and inspection/testing machinery, has further enhanced the quality standards achievable at Elexon’s Industry 4.0 facility, now offering 3D automated optical inspection, dual-side flying probe testing, selective soldering, PCB cleaning, and high-precision conformal coating.

The development of Elexon’s intelligent Industry 4.0 production facility has already resulted in the manufacturer securing a project with Tier 1 Australian Navy supplier, EM Solutions (EMS), delivering RF PCB assemblies for their marine Satcom terminals.

A milestone achievement for Elexon within the Defence space, is being approved as a supplier for Rheinmetall Group following and successfully bidding for work on Land 400 Phase 2 and 3 projects.

“Defence is a sector well suited to Elexon’s capabilities as an electronics manufacturer, even more so following our Industry 4.0 facility investment,” said Elexon Electronics CEO Frank Faller.

“Elexon is no stranger to high-precision, high-durability electronics, with its suite of wireless sub-surface mining solutions built to withstand the harshest of environments.

“The latest round of Industry 4.0 upgrades allows Elexon to produce extremely precise, durable, and meticulously tested electronics faster than ever before,” Faller said.

Industry 4.0 Manufacturing Facility

The Koh Young Technology Zenith2 is one of the most advanced true 3D AOI machines and another exciting addition to the Elexon Electronics facility, combining advanced vision algorithms and high-resolution 3D optics.

A major benefit of the Zenith2 is simplicity of use with AI-driven programming, offering up to a 70% reduction in programming time.

The SPEA 4060 S2 Flying Probe Tester was purchased for component testing, offering dual-side flying probing, as well as the option to use fixed probes, bed-of-nails, and more.

Another reason for choosing the 4060 S2 is its ability to test large boards, up to 20kg in weight, with high accuracy and rapid test times.

An Inertec CUBE.460 selective soldering machine allows Elexon Electronics to move from manual through-hole soldering to precise machine automated selective soldering; reducing manufacturing costs and guaranteed quality

Not only is manual labour removed from the soldering process, reducing time and eliminating human error, the CUBE.460 allows Elexon Electronics to solder complex PCB’s.

Precise cleaning requires a high-quality PCB cleaner and for this reason, Elexon Electronics recently invested in an MBtech NC25E PCB cleaner, to enhance and automate PCB cleaning capabilities.

A patented filtration system provides precise and efficient cleaning of PCB’s after reflow, and the use of an aqueous solution makes it possible to separate residues, ensuring a 100% closed-loop cleaning process to meet environmental demands.

Elexon Electronics has also acquired a Mycronic MYC50, replacing existing coating methods with a high-speed, high-precision solution.

The Mycronic MYC50 allows for the automation of high-performance conformal coating, for complex PCB’s.

All of the recent upgrades come together to form the backbone of Elexon Electronic’s Industry 4.0 manufacturing facility - a move made by the company to prepare for a serious push into the Defence manufacturing sector.

“We already have arguably some of the most advanced manufacturing capabilities within Australia, but we are constantly striving to improve and stay one, or even two steps ahead of the competition,” shared Frank Faller.

Login

Login